Handbook of reamers for horizontal directional drilling

- Ramunas Jasevicius

- Feb 5, 2023

- 4 min read

There are several types of reamers used in horizontal directional drilling (HDD), including:

Pilot bit: This is the initial tool used to create a small pilot hole in the ground.

Fluted reamer: This is used to stabilize and enlarge the diameter of the pilot hole. It has a cylindrical design with fluted blades or teeth that rotate and remove soil as the drill string advances.

Kodiak reamer: This is used to handle medium to hard soil conditions, including rock. It has a more aggressive design, with carbide cutters that are designed to handle a range of soil types.

Hole opener: This is used to create large diameter holes, typically in softer soil conditions. It has a disc-shaped design with cutting blades or teeth that rotate and remove soil.

Hole opener with cones: This is a variation of the hole opener, and is used in harder soil conditions. It has a cone-shaped design that is designed to handle harder soil and rock conditions.

Fly reamer: This is used to enlarge and finish the diameter of the borehole. It has a disc-shaped design with cutting blades or teeth that rotate and remove soil, creating a smooth, round hole.

To select the right horizontal directional drilling (HDD) reamer, the following factors should be considered:

Soil type: Soils can be classified as sand, clay, silt, rock, etc. Reamers are designed to handle specific soil types, so it's important to determine the soil type you'll be drilling in.

Hardness of soil: The harder the soil, the larger and more aggressive the reamer needs to be.

Soil conditions: Other factors such as moisture, density, and the presence of rocks or boulders can also impact the selection of reamer.

Borehole diameter: Reamers are designed to fit specific borehole diameters, so the diameter of the borehole must also be taken into consideration.

Project specifications: Finally, the specifications of the project, such as the required borehole depth, the material being drilled through, and the overall goal of the project, should also be considered when selecting a reamer.

The best reamer for a particular soil depends on several factors, including the soil type, hardness, conditions, borehole diameter, and project specifications.

Here's a general guideline:

Sand: For sand soils, a low to medium aggressive reamer is often sufficient.

Clay: Clay soils can be harder and more abrasive, requiring a medium to high aggressive reamer.

Silt: Silt soils can vary in their hardness and abrasiveness, so the choice of reamer will depend on the specific conditions.

Rock: Reaming through rock requires a high aggressive reamer with carbide cutters.

Mixed soils: For projects that involve drilling through a mixture of soils, a reamer with adjustable aggressiveness or a combination of reamers may be required.

How to select the right reamer?

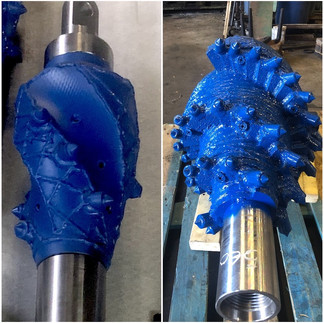

The Kodiak: The Kodiak reamer is a type of horizontal directional drilling (HDD) reamer designed for medium to hard soil conditions. It is well-suited for drilling through soil types such as sand, clay, silt, and rock. The Kodiak reamer features carbide cutters that are designed to handle abrasive and hard soils, making it well-suited for rock drilling.

The hole openers with carbide tipped cones: The best soil for using a hole opener with cones depends on the specific conditions and project requirements. Hole openers with cones are versatile tools that can be used in a variety of soil types, including rock, sand, clay, and silt.In general, hole openers with cones are well-suited for hard or abrasive soils, such as rock or heavy clay. The cones on the hole opener are typically made of carbide or other hard materials to handle these types of soils. It's important to note that the choice of a hole opener with cones will also depend on the specific conditions of the soil, such as its hardness and the presence of other materials, as well as the requirements of the project, such as the required borehole diameter and the presence of any obstacles in the borehole.

Fly reamers: Fly reamers are tools used in horizontal directional drilling (HDD) to enlarge and finish the diameter of a borehole. They are typically used after the initial borehole has been created using a pilot bit or reamer, and are designed to create a smooth, round hole that is ready for the installation of the pipeline or cable. Fly reamers have a disc-shaped design that consists of cutting blades or teeth that rotate and remove soil as the drill string advances. This helps to smooth out the borehole and create a uniform diameter, ensuring that the pipeline or cable can be installed with minimal damage or deformation. Fly reamers can be used in a variety of soil types, including sand, clay, silt, and rock, and come in a range of sizes to accommodate different borehole diameters.

Fluted reamers: Fluted reamers are tools used in horizontal directional drilling (HDD) to stabilise and enlarge the diameter of a borehole. They are typically used after a pilot bit has been used to create a small pilot hole, and are designed to remove cuttings and enlarge the borehole to the required diameter. Fluted reamers have a cylindrical design that consists of fluted blades or teeth that rotate and remove soil as the drill string advances. The fluted design helps to stabilise the borehole as it is being drilled, preventing collapse and ensuring that the borehole maintains its shape and diameter. Fluted reamers can be used in a variety of soil types, including sand, clay, silt, and rock, and come in a range of sizes to accommodate different borehole diameters.

Drillers often ask, what is the difference between the kodiak and fluted reamers, both of which look a bit similar to each other?

Kodiak and fluted reamers are both tools used in horizontal directional drilling (HDD) to stabilise and enlarge the diameter of a borehole. However, there are some key differences between these two types of reamers:

Design: Kodiak reamers have a more aggressive design, with carbide cutters that are designed to handle medium to hard soil conditions, including rock. Fluted reamers, on the other hand, have a more stabilising design, with fluted blades that help to remove cuttings and stabilise the borehole as it is being drilled.

Soil conditions: Kodiak reamers are typically used in medium to hard soil conditions, including rock, sand, clay, and silt. Fluted reamers are more versatile and can be used in a variety of soil types.

Versatility: Kodiak reamers are known for their versatility, as they can handle a range of soil conditions and have adjustable aggressiveness. Fluted reamers are typically used for stabilising the borehole and removing cuttings, but are not as aggressive as Kodiak reamers.

Comments